Custom CNC cutting creates beautiful displays and works of art that can help drive sales for companies. These displays can be used just about anywhere from trade shows, performance venues, store windows, festivals and can exhibit the uniqueness of a company’s brand, image, and voice. Learn more about how quality custom CNC work can help your company’s bottom line and brand awareness below!

THE SECRET OF SUCCESSFUL DISPLAY MARKETING

The expert design-build fabricators at DFlatt (David G. Flatt, LTD) find that their clients are looking for three ideal things in their product displays:

-

Vendors that complete projects on time.

-

Flawless execution of their design concepts for beautiful displays.

-

The workshop creating the fabrication does so at the right price point.

All three of these needs are best met with computer numerical control (CNC) cutting. CNC routers cut plywood and other wood, composites, plastics, aluminums, foams, and other materials with unparalleled precision and speed. Custom CNC wood cutting equipment isn’t just used for the creation of display panels. Fabricators can also use custom CNC cutting to create a wide selection of indoor and outdoor decoration, door carvings, signs, moldings, furniture, and musical instruments.

When the engineering is done properly, larger CNC cutters take human error out of the fabrication process. The computer that drives the cutter still needs input from designers, and it’s still necessary to plan out every step of the project before the first cut is made. However, no other method can transform a 4’ x 8’ sheet of plywood into an eye-catching display faster or more precisely. The design needs to be engineered before using the CNC machine so the pieces cut line up and fit into the final product properly.

CNC WOODWORKING SERVICES AND CNC CUTTING DESIGN

Every CNC cutting machine takes computerized information and translates it into instructions for a mechanized cutter to follow. CNC cutting design is the combination of art and technology that creates the instruction for the CNC cutting machine.

There are smaller, hand-held CNC wood cutting machines that can be used for turning plywood into more detailed displays. These smaller, hand-held devices speed up the process of making displays, but they also introduce the possibility of operator error.

At DFlatt we use an oversized, 5’ x 10’ CNC cutting machine capable of cutting hardwoods, softwoods, plastic and aluminum that can accommodate necessary pieces of the assembly of even the largest displays without the need for a human operator in the immediate proximity of the work. Our industrial-sized CNC cutting machine is more efficient, more versatile, and more accurate to the original design than smaller alternatives.

DFlatt’s Multi-Cam 5000 CNC router eliminates mistakes and wasted material. It enables the creation of a large number of complex projects that are not possible with handheld tools. DFlatt most often works with plywood, wood composites, plastic, and polyurethane foam, but its router can be fitted with steel bits as needed.

CNC WOODCUTTING IS NOT A DO-IT-YOURSELF PROJECT

It may seem as if operating a CNC wood cutting machine is easy but the engineering, design, and construction to execute a project can be quite complex. At Dflatt we handle all of that for you and are readily available for any of your custom CNC machining service needs. Our new Multi-Cam 5000 CNC machine with two cutting bits that will halve the operational time since it works both sides of the piece at the same time. We can also help you create the design you are looking for. Our CAM software can import models from any major CAD programs. We have custom CNC cutting engineers that will work with you to turn your great ideas into a reality.

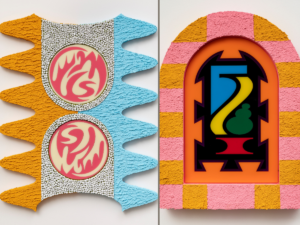

Although you can purchase a CNC cutting machine, it is extremely expensive. By working with Dflatt you can receive the top-quality, custom project of your dreams without having to purchase and upkeep a machine. We will help you engineer your idea. For example, we once created a 14’ tall gummy bear. Using a CNC machine, “we used a 3D printer approach, but with thicker layers, since it was plywood,” for the artist WhIsBe. Thus, a lot more goes into these projects than just cutting material, so leaving it up to a professional that can handle the engineering, design, construction, and assembly is in the best interest.

Furthermore, the most intricate and eye-catching display projects require the largest and most complicated CNC cutting equipment and the right team. For complex projects, trust the experts. With decades of experience, DFlatt can help take your design from idea to engineering through the fabrication. Our Multi-Cam 5000 provides the ability to create those complex projects that would be difficult or near impossible to create by hand. With features like precision and high speed, large scale art production, custom sign fabrication, furniture, and set design is made possible with shorter completion time. Only companies that are willing and able to invest substantial work hours and capital costs should attempt to have their own CNC Department as a lot more goes into these projects than just cutting.

Using a professional, experienced vendor like DFlatt is the hassle-free, cost-effective option. Additionally, DFlatt offers various worthwhile advantages that other CNC contractors do not.

CNC CUTTING SERVICES TAKE CARE OF YOUR DISPLAY FABRICATION NEEDS.

At David G. Flatt, LTD we can take your design from idea to engineering through the fabrication process. We are ready to handle any custom CNC project no matter if it’s large scale or small. Save the expense of purchasing and upkeep a machine by trusting the top experts here at Dflatt. If you are looking for ways to bring your creative aspirations to life, our supportive team of designers can capture your vision and bring it to reality. Submit a custom CNC work cost quote request or give us a call at (718) 937-7944 to learn more. Or contact us to set up an appointment to visit our shop at 38-42 Review Long Island City, NY 11101. We service Brooklyn, Queens, Manhattan, Long Island City, and the greater NYC area.